All companies depend on their supply chain. From COVID to Brexit, and from natural disasters to HGV driver shortages and the semiconductor shortage, supply chains today are under attack, which have led to an array of issues for production, manufacturing, and consumers.

Supply chain visibility can reduce this disruption and enable insight into how to mitigate potential risk, especially when providing visibility at the multi-tier level, which Versed AI offers through its cutting-edge Natural Language Processing and Machine Learning technology.

2020 - An Annus Horribilis for Supply Chains

The Covid-19 pandemic has wrought havoc on corporate supply chains. In 2020, there was a $4 trillion loss for US and European companies solely due to supply chain disruption, which equates to 6-10% of a company’s annual revenue. Proper multi-tier supply chain visibility would have helped reduce these costly losses.

A range of factors can disrupt the supply chain and incur great cost; the semiconductor shortage alone is responsible for expected costs to the global automotive industry of $210 billion in revenue in 2021, nearly double the $110 billion projected in May 2021. Shockingly, this is up by 81.5%, from an initial forecast of $60.6 billion in late January 2021.

To make sense of the level of global disruption facing supply chains currently, it’s important to assess the varying issues that procurement and supply chain risk teams are dealing with.

Natural Disasters:

Natural disasters such as flooding, fires, hurricanes, and earthquakes wreak devastation across the globe, and supply chains aren’t immune from this. Halted factory production, damaged equipment, and staff shortages as a result all contribute to lengthy delays in production and distribution, causing companies to lose money, consumer trust, and suffer scheduling setbacks.

One of the fasting growing disasters is flooding, the disruption of which has impacted Europe heavily in recent times. In July 2021, production was halted for over 48 hours at a Mini production line in the Netherlands, due to torrential rainfall and flooding, impacting an already tight global Mini supply.

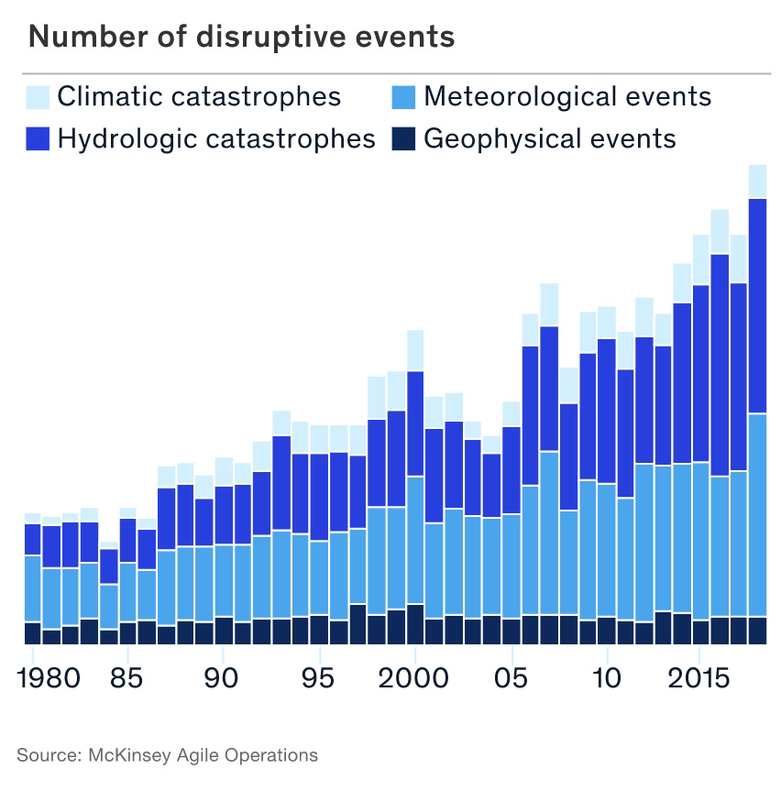

A 2020 report by analysts at consultancy McKinsey warned that the “economic toll caused by the most extreme events has been escalating”. Thus, the need for mitigation of disruption from the increasing frequency of natural disasters is more prevalent than ever. In July 2021, the city of Zhengzhou in China suffered severe flooding after heavy rains. Versed AI helped a client assess potential disruption from the floods, looking four tiers into their supply chain to check for companies with manufacturing locations in Zhengzhou. Although there was no exposure identified at tiers 1 and 2, Versed AI found an important supplier with 4 factories in Zhengzhou, who cropped up multiple times across tiers 3 and 4. This rapid analysis enabled the client to ask the right questions of their supply chain, assess the size and likelihood of future disruption, and take early mitigating action as needed.

Global Pandemics:

In recent times, the Covid-19 pandemic has been the most widely attributed cause of supply chain disruption. The pandemic revealed fragilities across global supply chains across in most industries. IBM mention that “the knock-on impacts of China’s shutdowns early in 2020 sparked strong interest in geographical diversification of supply chains”, evidencing the need for increased domestic production.

Whilst manufacturers and retailers have been hit vastly by the pandemic, other industries have suffered greatly too. Bloomberg highlight a survey of 900 US and European procurement professionals across the biggest companies in the technology, aerospace and defence, and financial services sectors, who state that on average, they’ve each lost $184 million in revenue over the last year due to supply chain disruption, namely Covid-19.

Small businesses were hugely affected by the pandemic, as they lacked the infrastructure to deal with the knock-on effects. Local corner stores ran into huge trouble when Walkers Crisps stopped producing single packs of crisps in response to the pandemic’s disruption, in order to reduce the number of stock-keeping units and simplify the production process. This change had little impact on supermarkets, where most shoppers select multi-packs, but corner stores typically sell crisps in single packets, so they lost their usual source of supply and had to work rapidly to identify alternative solutions.

A 2021 survey found that 59% of small business owners faced longer delays receiving goods during the pandemic, whilst 76% experienced an increase in the price of goods, and 1/3 of mid-sized firms surveyed by accountancy firm BDO said they’d had to reduce their product lines or services as a result of the consequences of the pandemic. This meant that an array of small businesses went under during the pandemic as they didn’t have contingencies in place to cope with the extent of disruption. In the US 100,000 establishments that temporarily shut down due to the pandemic are now out of business.

Whilst we don’t have the foresight of future pandemics, or supply chain disruption, companies must begin to forge smarter, sustainable supply chains. Companies should leverage artificial intelligence and implement visibility to provide them with clear contingency plans against the unanticipated.

Geopolitics

Across the British economy, widespread disruption has led to a crisis compounded by the fallout from Covid, alongside national factors including Brexit, and most recently, severe fuel shortages and lack of HGV drivers. Currently, supply chain disruption in the UK is at its worst level since the 1970s. The shortage of drivers has resulted in chaos across Britain, with the ongoing crisis estimated to last for at least a year, and the national water supply was even threatened as treatment chemicals couldn’t be delivered due to the crisis.

Geopolitics incurs short-term and long-term risks. Longer-term impacts of geopolitics include civil unrest, war, and terrorism. These have damaging effects on supply chains, such as delays in production and shipping if a company relies heavily on supply from a foreign country that’s experiencing unrest.

Notably, in February 2021, South Korea’s Illjin Materials secured their first shipment of copper foils to Samsung, critical for computer chip production. This new relationship is significant, as this new supply reduces South Korea’s dependence on components and materials from Japan, a country with whom South Korea has poor geopolitical relations.

Trying to remove these geopolitical disruptions from supply chains is tenuous and lengthy, however, reducing this risk can have great benefits across the supply chain. Firstly, it’s essential to obtain wide scope visibility across the supply chain to see areas that may be affected by geopolitics and civil unrest. With this visibility, a company is well-equipped to create a decisive action plan to mitigate this risk.

Trade Disputes

Trade disputes can result in widespread disruption across supply chains. Disputes arise when a World Trade Organisation (WTO) member government believes that another member government is violating an agreement or a commitment that has been made in the WTO.

US–China sanctions have a significant impact on supply chains, particularly as they are frequently subject to change as geopolitical relations between the two countries become more volatile. The United States imposes economic and trade sanctions on individuals, entities, and jurisdictions throughout the world based on US foreign policy and national security goals. This has been particularly highlighted across the increased fear of spy technology, documented prolifically in the media with the US stating that Huawei could be used by China for spying, via its 5G equipment.

Trade relations and geopolitics are fundamental to stable supply lines. This year, European gas shortages have resulted in a crisis. Prices have risen exorbitantly, to almost five times the level they were in 2020. Exacerbating this is the reliance on Russia, with whom trade relations are tenuous. Russia, is one of Europe's biggest natural gas providers, and there have been accusations of the country intentionally withholding supplies, furthering tensions, and displaying the need for new solutions.

Sanctions risks are becoming an increasing concern for companies, and this summer Versed AI was able to help a client assess whether there was any impact on their supply chain from the newly updated US sanctions list. Fortunately they were not, but staying on top of evolving sanctions regulations adds an extra layer complexity to procurement and supply chain risk.

Worldwide supply chains are being reformed, as companies globally try to cut their exposure to rising geopolitical tensions, whilst governments seek to boost domestic industries by onshoring manufacturing.

Logistics Bottlenecks

Logistics bottlenecks are some of the most unexpected events in supply chain disruption, with the most notable in recent times being the blockage of one of the largest container ships, The Ever Given, in The Suez Canal during March 2021, the cost of which amounted to 12% of global trade and was holding up trade valued at over $9 billion per day. The Suez Canal blockage emphasised just how disruptive unexpected events can be to the global economy, especially in a marketplace that lacks contingency plans and disruption forecasts. The disaster is symptomatic of a wider problem, as supply chains become increasingly complex and lengthy, and the size of ships required to efficiently transport goods around the world increases due to ever-growing consumer demand.

These logistical bottlenecks have clear implications for business. With delayed deliveries impacting production lines, costs are rising across industry. Global supply chain shortages have vastly impacted business. Labour shortages, congested ports, increased demand, and a lack of supply mean that prices are rising in every industry. The price of shipping a 40-foot container to the West Coast of The United States has soared to over $6,000, up 63% since the start of 2021, and more than three times the price a year earlier.

Cyber Attacks:

As the digital world becomes omnipresent in all aspects of our lives, the threat of cyber attacks has grown substantially. These can lead to severe impact on supply lines, most notably the Maersk cyber attack in June 2017, whereby the Danish transport and logistics giant, best known for its shipping containers, had their supply chain significantly compromised by malware. Most of the company’s systems and applications were wiped out, alongside access to almost all of their data, causing significant disruption to their customers’ supply chain, as Maersk carries almost one fifth of the containers moved globally. Maersk managed to spring back after reconfiguring the resilience of their supply chain, but the attack paralysed the company for 2 weeks and cost them $250-$300 million. One of Maersk’s successes in dealing with the crisis was their transparency about the attack, leveraging its reputation as a trusted global brand to overcome certain follow-on problems, thus highlighting the benefits of transparent supply chains.

There are wide ranging causes of disruption, all leading to increased costs, delayed production, and wide-reaching impact across industry. As disruption increases, multi-tier visibility is paramount. Versed AI offers clear insights into supply chain networks, providing data that procurement managers can analyse to identify potential disruption. The visibility offered includes identifying alternative suppliers and locating specific addresses of factories that may be affected by unexpected, disruptive situations.

How Disruption Affects Business

Supply chain disruptions impact business in many ways, from reputational damage to higher operating costs. A survey from GEP identified that 38% of companies with revenue greater than $1 billion reported significant damage to their company's brand and reputation, with clear reputational costs in terms of customer complaints and damage to brand reputation as companies struggled to maintain supplies of their goods. These consequences can be hard to recover from, as company’s credibility may be hard hit. A further 33% said that their operational costs increased significantly as a direct result of supply chain disruptions.

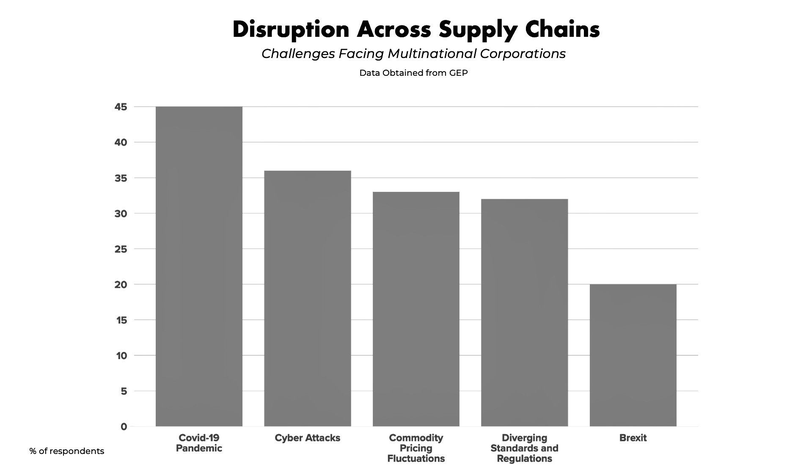

There are a range of disruptive elements wreaking havoc across global supply chains, with the GEP report highlighting COVID-19 as the most significant, with 45% stating that the pandemic severely disrupted their supply chain. However, a range of other factors are contributing to the challenges facing multinational companies, with 36% referencing cyberattacks and 33% facing commodity pricing fluctuations as significant disruptors.

Growing Visibility: Why It Matters

Corporates have recognised the importance of supply chain analytics and are allocating more money to it. In total, $16bn is expected to be spent by companies in 2028, which represents a 17% annual increase in budgets for supply chain analytics. This growth is largely attributed to mounting supply chain disruption, as companies increasingly recognise that they need broader visibility of their supply chain.

Versed AI is a crucial protective component for a company’s risk prevention strategy and operational efficiency, helping to mitigate risk imposed from disruption, alongside enabling insight into ESG factors for responsible business conduct, such as modern slavery risk, and using multi-tier visibility to expose common sub-tier suppliers who could lead to aggregation risk. By mapping a company’s supply chain, Versed AI’s knowledge graph identifies supplier relationships, common sub-tier suppliers and even exact factory addresses, to provide a clear insight into the depths of a company’s supply chain.

A survey from the Economist highlighted that 38% of respondents reported damaged brand reputation due to knock-on effects from supply chain disruption, whilst 23% stated a loss of regular customers, evidencing the filtration of disruption from manufacturing processes into consumer satisfaction.

Companies are finally starting to pay attention to the importance of visibility in their supply chain, with 60% of respondents in a major GEP survey agreeing that resilience in their company's supply chain is more important than speed and efficiency, evidencing a major shift in operational strategy. Multi-tier visibility improves network agility, making a company more adaptable to change and unforeseen circumstances, and more equipped to deal with problems before they arise.

Lowering Cost

50-75% of company costs are directly influenced by the supply chain, so this current period of disruption is an opportunity to take a closer look at the supply chain and align it to shifting needs and conditions, as mitigating disruption in the supply chain can reduce costs substantially. Optimal supply chains can lower business costs by 15%, highlighting how crucial effective management of the supply chain is.

Digital Transformation: The Future of AI

AI’s use in supply chains is growing rapidly, with its success apparent quickly after implementation. McKinsey highlight that successfully implementing AI-based supply-chain management has enabled companies to improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%, evidencing its effectiveness.

There’s an increasing call for businesses to undergo digital transformation, with AI notable in supply chain management. AI is more efficient than current methods, and Versed AI’s technology provides continual updates across their broad knowledge graph, identifying the depths of supply chain relationships at the nth tier. Current processes used by companies tend to be manual, time-consuming and are not cost-effective. However, Versed AI offers game-changing technology, developed at Cambridge University. Versed AI’s capabilities include analysing vast quantities of data, understanding relationships, providing visibility into operations, and enabling better decision making, providing structure across industries riddled with disruption.

EY reinforces the necessity of the digitisation of the supply chain, and state that end-to-end visibility is an essential component for an effective supply chain as current supply chain infrastructure is inadequate and won’t sustain in the long-term as disruption mounts. Digital processes provide a broader view across increasingly complex commercial ecosystems.

In Conclusion

This current period of significant disruption is an opportunity to take a closer look at companies supply chains, and align them to shifting needs and conditions. Adopting multi-tier visibility in a company’s operations enables insight into potential risks, making way for effective, pre-emptive action.

Enhanced supply chain resilience is necessary for mitigating the effects of disruption on your business, and implementing multi-tier supply chain visibility is a key element in doing so.

Learn more about how Versed AI can help protect your business from disruption